Advanced Explosion Proof Capability.

Technolube EXPL

The Electromechanical Industry's First Highest Explosion-Proof Certified Lubricator

Features & Advantages

Global Explosion Proof Certificates:

IECEx: Ex ic II.C T/T Gc (International Certification)

ATEX: II, II, G Ex ic I, C T5/T4 Gc (EU Certification)

KCs: Ex ic IIB T4 (Korea Certification)

NEPSI: Ex ic B,C TS/T Gc (China Certification)

ETL: Class I, Division 2, Groups A, B, C, & D, T4

Class Il, Division 2, Groups F. G, T4 (North America Certification)

IP Code: 1P65 - dust tight and protected against water jets

Applications: Specifically designed for safe use in highly hazardous area containing flammable medium (ignitable gas, vapours etc. such as hydrogen and acetylene) in the air

Multipoint Installation: Up to 8 lube points using Lithium battery by Max. 60bar (870psi) operating pressure.

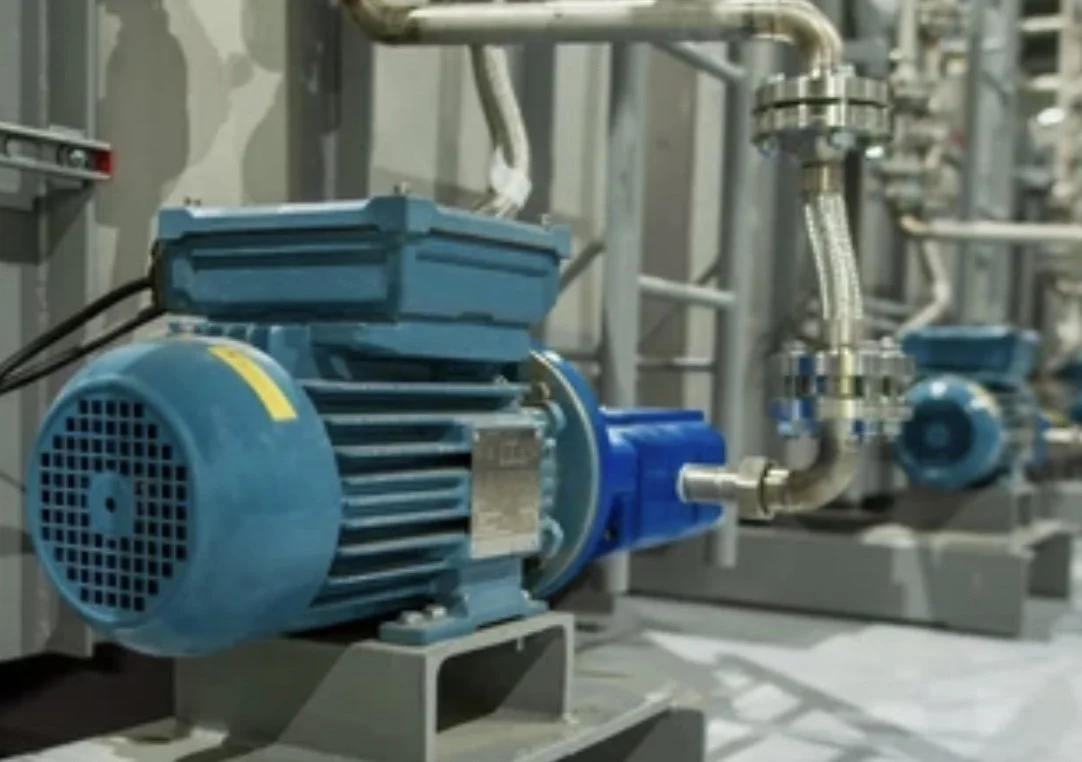

Typical Applications

Electric motors & pumps used in petrochemical plants, transportation of crude oil/natural gas, hot/cold rolling equipments in steel industry, cooling water treatment facilities in power plants, etc.

Applications in environments where flammable gases or vapours are present in the air in quantities sufficient to produce explosive or ignitable mixtures

Cooling tower pumps & motors at hydroelectric, thermal and nuclear power plants

Remote Installation:

Max 6m (20ft) with tube

Multi-Point Installation:

Lithium Battery: Max 3m (10ft) with tube (up to 8 tube points)

Dispensing Volume Size

0.34ml/stroke (@20C 0r 68F)

Certifications & IP Code

ATEX, IECEX, KCs, ETL, NEPSI, CE, IP65

Product Details

Grease Pouch Capacity:

60ml/120ml/240ml/480ml (pre-set)

Power Supply:

DC 4.5V Battery Pack (Alkaline, Lithium Battery Pack)

480ml - Lithium Battery Pack

Operating Pressure:

30bar - 60bar (435-870psi)

Operating Temperature:

-15C - 50c (5F - 122F)

Dispensing Periods:

60ml 1 - 12 months

120ml-480ml: 1, 2, 3, 6, 9, 12 months